In todays session we looked at examples of print that we asked to bring in. We was told to bring in a range of different printed products that have been printed using different methods. We then explored colour by looking at different printed materials and methods which included...

Ruby Lith Screen Print

Rubylith is a brand of masking film. Today the brand has become genrecized to the point that it has become synonymous with all coloured masking films.

Rubylith consists of two films sandwiched together. The bottom layer is a clear polyester backing sheet. The top layer is a translucent, red coloured, self adhesive emulsion. It is designed to be both easy to cut with a knife and light safe for use with orthochromatic films.

Rubylith is used in many areas of graphic design, typically to produce masks for various printing techniques. For example it is often used to mask off areas of a design when using a photoresist to produce printing plates for offset lithography or gravure. It is also frequently used during screen-printing.

Spot Colour Printing

Spot colour printing creates brighter, more vibrant results, but with a smaller color range. When printing in single (spot) colours, a single colour ink (normally with a Pantone reference number) is applied to the printing press roller. If there is just one colour to be printed, there will be a single plate, and a single run of the press. If there are two colors, there will be two plates and two runs, and so on. The colours are layered onto the paper one by one. This can be expensive the more Spot Colours that you have in your work but can create some great results when used innovatively and can also be used cheaply using clever methods.

Spot colour printing would be typically used for jobs which require no full color imagery, such as for business cards and other stationery, or in monotone (or duotone etc) literature such as black and white newspaper print.

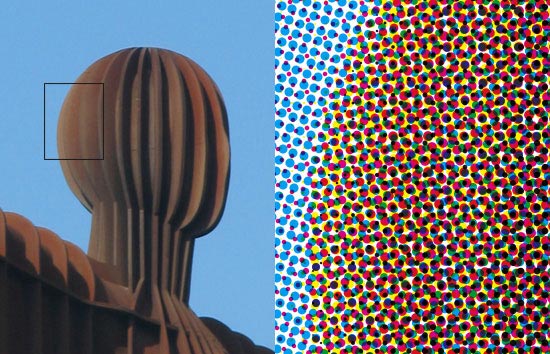

Four Colour Printing (CMYK)

4 colour process printing involves the use of four plates: Cyan, Magenta, Yellow and Keyline (Black). The CMYK artwork (which you will have supplied) is separated into these four colors – one plate per color. The four CMYK inks are applied one by one to four different rollers and the paper or card (‘stock’) is then fed through the printing press. The colors are applied to the stock one by one, and out comes the full color (4 color process) result.

If the plates are aligned correctly on the press, the registration is accurate, and the result is sharp and clear. If the plates are misaligned, the registration is inaccurate, and the result is blurred and poor.

This teaches us that no matter how good the artwork that left our studio was, the project can still be messed up by a less-than-conscientious printing company. For potentially expensive print runs it is wise to press-pass the finished product, which means actually standing at the end of the press and checking the quality of the finished product as it comes out of the machine.

Monochrome & Duotone

One and Two Colour Printing

Monochrome

Duotone

Monochrome describes something that is all one color or done in black and white. This helps saves costs dramatically as there is only one colour plate being used to print, rather than four in the CMYK full colour prints. It reduces what you can do with the print but also can have some really cool effects, aiding your design more than anything. Duotone is adding another colour plate to the work. By printing with two complimentary colours, you can simulate a wide range of tones and still save on cost by only having two colour plates in the run. It gives more definition and tones than the flat one colour print.

Trio Chromatic Inks

The ink is not dense, meaning that it overlaps other inks that are printed on the page.

Three Colour Print

This is a print using three colour plates.

Workshop

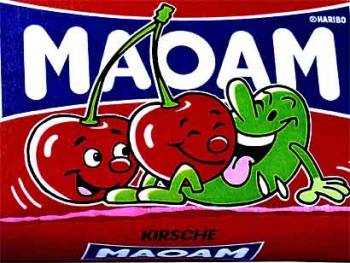

We also used Magnifying glasses to look closely at some of the different printed products that we had collected.

If you look at a full color magazine through a magnifier, you'll see that all the colors are made up of CMYK patterns, as shown by the above image. If you look at an area of spot color through a amgnifier, there will be no screen - it will show an area of solid, unbroken color (unless the grayscale or bitmap image it is applied to has a halftone screen of its own).

I then took some photos of the prouducts I had brought in and tried to figure out some of the print processed used to print them...

Red Stripe Can - This can has been printed with three colours, white, black and the glossy red which looks like it could be a spot colour. The process would have been pad printing. Printing onto a 3 dimensional object.

Egg Box - The print on the inside of this egg box has been printed onto the pulp like stock and it's hard to distinguish it's print method. It's one colour which tells us that it's monochrome and could have been screen-printed or litho printed.

Leeds College of Art Booklet - This LCA booklet has been nicely printed and put together. The stock of the actual booklet is matt and the front and back page looks to be printed monochrome. When you look inside however, the book is printed in the CMYK four colour process and there has also been a spot colour glossy black used on the front, printed onto a different stock.

Tobacco Pouch - The material used for the tobacco pouch is really poor stock, designed to be thrown away after usage, but the print looks higher quality. In this case, it looks to be a four colour, CMYK print. The poor quality stock means that the product can be produced as a mass scale without loosing too much of the print quality.

Warehouse Project Flyer - This flyer has been printed really well and cleverly to help save costs. There is two colours throughout the flyer which are black and grey and there is also a spot colour black or possibly a spot varnish on the front, making it look more luxurious and classy but also keeping the cost down with no colour and greyscale print (grey text, black background).

Chinese Newspaper - Most newspapers including this one have been printed in the four colour CMYK print process and onto really cheap newsprint to keep costs down on such a mass scale. There is no special print methods other than the CMYK plates used for the