Definition : To carve or mold a design on (a surface) so that it stands out in relief: "an embossed brass dish". To decorate (a surface) with a raised design.

What is Embossing?

Embossing refers to the creation of an impression of some kind of design, decoration, lettering or pattern on another surface like paper, cloth, metal and even leather, to make a relief. In regular printing or an engraving, plates are pressed against the surface to leave an imprint. In embossing however, the pressing raises the surfaces adding a new dimension to the object.

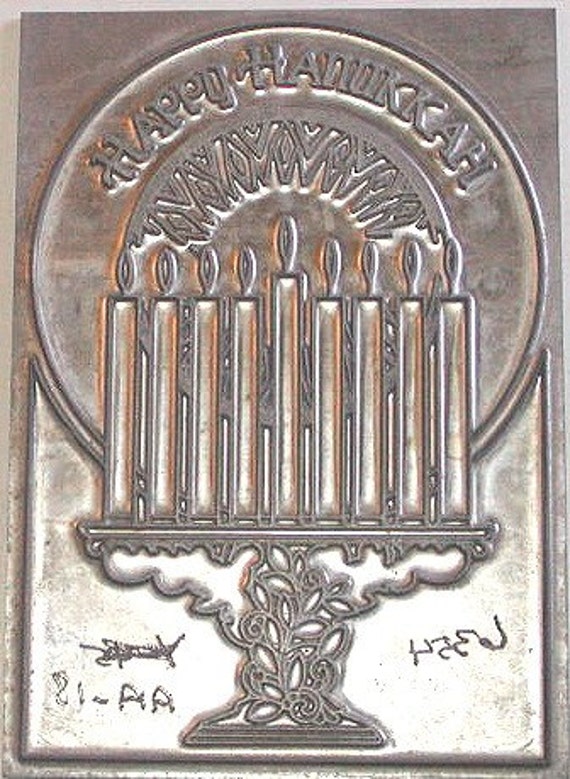

Blind Embossing Die

Embossing involves the creation of an impression by placing the dies in contact with the stock under high pressure. Different kinds of paper show different kinds of embossed effects. There are also many different kinds of embossing that can be done like blind embossing, tint embossing and glazing to achieve different results. The process of embossing is relatively inexpensive and has many uses.

Uses of Embossing

Embossing is an elegant process that changes the nature of the material that has been embossed. More often than not it elevates the standard and quality of the product. A notary’s embossed seal can give much weight to a regular piece of paper.

Embossed Wedding Invitation

Similarly, an embossed wedding card immediately changes the entire meaning conveyed by the invitation. The recipient is informed not only about the wedding but also that it is going to be a high profile wedding and an elegant ceremony.

Braille Embossed Medication Packaging

Bank Card Details Embossing

Process of Embossing

There are three types of metals that are used for embossing dies. Depending on the shape of the image, the texture to be created and the length of the run you can select the metal.

Types of Metal Embossing Dies

Magnesium Embossing Die

Magnesium dies are used for easy embossing projects that have short runs. The designs are large and uncomplicated. Magnesium also allows for special hand tooling. They are the least expensive of all dies, photomechanically etched. Better for short runs up to 5,000 impressions and for use on smoother stocks.

Brass Embossing Dies

Brass dies are the most popular embossing dies. They are very flexible and give the embosser leeway to create fine lines, sculptured images, combo foil stamping and embossing. They are also very good for images requiring extensive hand tooling. You can make brass dies by machines or by a semi-photographic process. The photograph is transferred onto the die to use as a guide for drawing. This is the most expensive type of die. It is created with a manual drawing machine called pantograph or created entirely by hand. It is used for long runs, some in excess of 1.000,000 impressions. It provides the highest quality reproduction, giving sharp detail and clean bevels.

Copper Embossing Die

Copper dies are used as an in between to magnesium and brass. However copper dies do not permit hand tooling. They are mid range cost and used for runs up to 100,000 impressions, They provide better detail and reproduction of fine lined copy and images.

Source - http://www.falcontec.co.uk/index.php

Roatary Embossing Example - Colourless Coke Cans

A convex logo substitutes colorfully sprayed can. Naked can help to reduce air and water pollution occurred in its coloring process. It also reduces energy and effort to separate toxic color paint from aluminum in recycling process. Huge amount of energy and paint required to manufacture colored cans will be saved.Instead of toxic paint, manufacturers process aluminum with a pressing machine that indicates brand identity on surface. By Harc Lee

Choosing The Stock

Paper textures play an important role in embossing. Sometimes clients select a texture paper and use embossing to smooth out the paper where it is least expected. At other time a smooth paper is used but the emboss is textured for a stunning finish.

Heavy, long fibered sheets make the best kind of paper for embossing. Lightweight, heavy coated or varnished papers are not good for embossing because they crack easily. Also recycled paper is to be avoided for embossing. In general the more processed a paper is the weaker it becomes and cannot withstand the pressures of embossing.

The depth and the degree of bevel achieved are determined by the stock. A thicker stock can offer more dramatic embossing effects because the impression can push deeper into the paper and varying levels of relief become possible.

Uses of embossing

Multi-Level Embossing Die gives 3D Results

Embossing is often used for company logos or as accents surrounding logos. It is used for borders or highlights surrounding images. Another common use is to create elegant accents for distinctive symbols, images, graphics, or lines. If a multilevel or sculptured die is used, there will be varying depths to the embossing, giving the image a distinctive 3-D effect. Embossing is occasionally used for security. Embossed seals or symbols of authenticity add security to government forms, legal documents, and corporate papers, however, embossing is considered an older form of document security, as more alternatives in print technology continue to be developed.

Blind Embossing

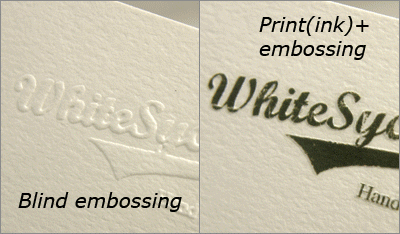

Blind Embossing is the term given to an embossed image that is not stamped over a printed image, not foil stamped, and the resulting raised image is the same color as the paper is blind embossing.

Here are a few examples of blind embossing...

Embossing Examples

Colour Emboss

Debossing

The deboss process is the same as that for embossing, except debossing raises the material around the die impression rather than raising the design area itself. Brass, copper, and magnesium dies are used in the debossing process as well.

There are several debossing techniques. A blind deboss is used with screen-printing or foil stamping. With the screen process, the art or design is first printed onto the material and then the outline of the print is debossed using a die exactly registered to the silk screen print. In foil stamping, the foil is transferred to the material using a special die and then the same die is used to deboss the area. Debossing is less complicated than embossing, and when done in conjunction with silk screen printing, it results in a colorful and more detailed rendering of artwork and lettering.

Debossing and embossing are preferred methods of imprinting onto materials such as leather or vinyl. debossed and embossed leather or vinyl make elegant reproductions of a company logo or name.

There are several debossing techniques. A blind deboss is used with screen-printing or foil stamping. With the screen process, the art or design is first printed onto the material and then the outline of the print is debossed using a die exactly registered to the silk screen print. In foil stamping, the foil is transferred to the material using a special die and then the same die is used to deboss the area. Debossing is less complicated than embossing, and when done in conjunction with silk screen printing, it results in a colorful and more detailed rendering of artwork and lettering.

Debossing and embossing are preferred methods of imprinting onto materials such as leather or vinyl. debossed and embossed leather or vinyl make elegant reproductions of a company logo or name.

Debossed in Leather

Debossing Examples

Sadly it seems nearly all the photo links are broken so I can not see the examples.

Nice post. Embossing is easy but cost effective method. I tried embossing die sets and it really enhances look of a product.

Leave your comment